BEV advancements are driving sales, but vehicle safety and reliability will ensure long-term viability

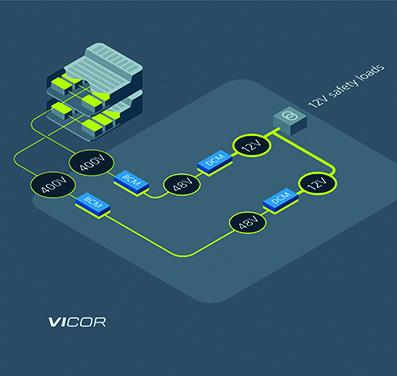

Innovative power architectures using power modules provide power redundancy and improve overall safety and system performance By Patrick Kowalyk, Automotive FAE,Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

The EVA series are suitable for on-board chargers, inverters and DC/DC converters, as well as battery management system and wireless power transfer implementations.

The EVA series are suitable for on-board chargers, inverters and DC/DC converters, as well as battery management system and wireless power transfer implementations.

Takahiro Yoshida, general manager of ceramic capacitor business unit, marketing group, at Murata, commented: “With EV powertrains moving to higher voltages, longer creepage distances are now being required. Unfortunately, at the same time, constituent components need to take up less physical space”. He believes the use of resin moulding will allow the EVA series MLCCs to combine a compact form factor with extended creepage.

Developed in accordance with IEC60384-14 requirements, the Y2 class MLCCs will suppress common mode noise in next generation electric vehicles (EVs). The MLCCs are housed in surface mount packages (each with a 12.7 x 6.0mm footprint and a profile of 3.7mm. These compact components have 305VvAC / 1500V DC voltage ratings and support 10mm creepage distances. These characteristics enable the MLCCs to address the greater isolation that migration to 800V powertrains will require while remaining aligned with the need for miniaturisation in modern automotive systems.

The capacitance values of the EVA series range from 0.1 to 4.7nF. The MLCCs are AEC-Q200 qualified and have an operation temperature range of -55˚C to 125˚C. They have elevated withstand voltages of 2000V AC/60s and 4000V DC/60s. They also exhibit low equivalent series inductance (ESL), so performance is not impaired at high frequencies. The metal terminal arrangement is also claimed to increase elasticity. Formation of solder cracks and deflection cracks is mitigated for long term reliability, said Murata.

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media