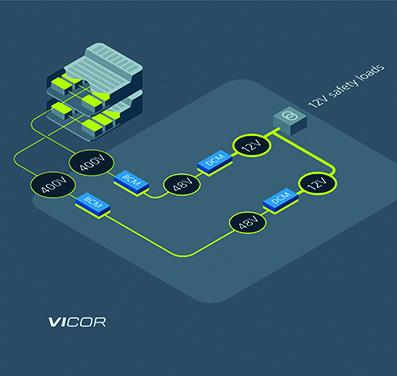

BEV advancements are driving sales, but vehicle safety and reliability will ensure long-term viability

Innovative power architectures using power modules provide power redundancy and improve overall safety and system performance By Patrick Kowalyk, Automotive FAE,Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

Developed with the Clean Sky consortium, Microchip’s BL1, BL2 and BL3 families are qualified to stringent aerospace standards for AC-DC and DC-AC power conversion. They are designed for efficient electrical systems to replace pneumatics and hydraulics which currently power everything on aircraft from on-board alternators to actuators and auxiliary power units (APUs).

Developed with the Clean Sky consortium, Microchip’s BL1, BL2 and BL3 families are qualified to stringent aerospace standards for AC-DC and DC-AC power conversion. They are designed for efficient electrical systems to replace pneumatics and hydraulics which currently power everything on aircraft from on-board alternators to actuators and auxiliary power units (APUs).

The modules were developed with Clean Sky, a joint European Commission (EC) and industry consortium and are claimed to be the first aerospace-qualified baseless power modules enabling higher-efficiency, lighter and more compact power conversion and motor drive systems.

According to Microchip, they provide greater efficiency in AC-to-DC and DC-to-AC power conversion and generation through the integration of its SiC semiconductor technology. They are 40% lighter, thanks to the modified substrate and the company also claims the design also produces an approximate 10% cost savings over standard power modules that incorporate metal baseplates.

The BL1, BL2, and BL3 devices meet all mechanical and environmental compliance guidelines in RTCA DO-160G - the “Environmental Conditions and Test Procedures for Airborne Equipment,” Version G (August 2010). RTCA is the industry consortium that develops consensus on critical aviation modernization issues.

The modules are available in low-profile, low-inductance packaging with power and signal connectors that designers can solder directly on PCB, helping to speed development and increase reliability, says the company. They are the same height between the modules in the family which enables them to be paralleled or connected in a three-phase bridge and other topologies as power converters and inverters.

The modules incorporate SiC MOSFETs and Schottky barrierdDiodes (SBDs) to maximise system efficiency. They are in packages delivering 100W to more than 10 KW and in a choice of topologies including phase leg, full bridge, asymmetric bridge, boost, buck and dual common source. Voltage ranges are from 600V to 1200V in SiC MOSFETs and IGBTs to 1600V for rectifier diodes. And 75 and 145A SiC carbide MOSFETs and 50A (IGBT) and 90A (rectifier diode outputs).

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media