BEV advancements are driving sales, but vehicle safety and reliability will ensure long-term viability

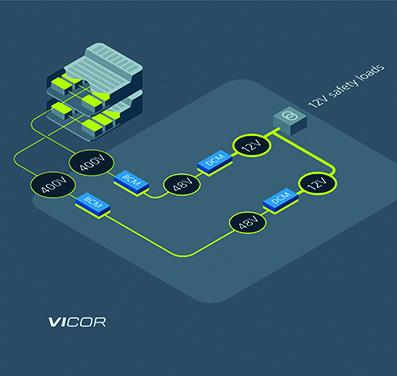

Innovative power architectures using power modules provide power redundancy and improve overall safety and system performance By Patrick Kowalyk, Automotive FAE,Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

The traction inverter manufacturer will use STMicroelectronics’ SiC die in the traction inverter platforms for several current and future Volvo Car battery EVs (BEVs). ST will supply its third generation 750V SiC power MOSFETs dice for the proprietary Viper-based power module. This power module is used in BorgWarner’s traction inverter platforms for several current and future Volvo Cars electric vehicles.

The traction inverter manufacturer will use STMicroelectronics’ SiC die in the traction inverter platforms for several current and future Volvo Car battery EVs (BEVs). ST will supply its third generation 750V SiC power MOSFETs dice for the proprietary Viper-based power module. This power module is used in BorgWarner’s traction inverter platforms for several current and future Volvo Cars electric vehicles.“This collaboration will give Volvo Cars the opportunity to further increase the attractiveness of our electrical vehicles with longer range and faster charging. It will also support us on our journey towards being fully electric by 2030 and strengthen our increased vertical integration and our control of critical components," says Javier Varela, Chief Operating Officer & Deputy CEO, Volvo Cars.

The companies collaborated, with ST’s technical team matching die with the Viper power switch to maximise inverter performance in order to deliver a compact, cost-effective architecture. According to ST, the collaboration provides the high volume capability that is required by the quickly growing EV market.

Marco Monti, President, Automotive and Discrete Group, STMicroelectronics, commented: “We are committed to expanding SiC capacity and to reinforcing our SiC supply, including through vertical integration, as we ramp up volumes to support our global automotive and industrial customers in their shift to electrification and higher efficiency”.

ST’s high-volume STPOWER SiC products are manufactured in its fabs in Italy, and Singapore. Advanced packaging and testing take place in back-end facilities in Morocco and China. ST has also expanded its wide bandgap manufacturing capacity with a new integrated SiC substrate manufacturing facility in Catania, Italy, where the company’s power semiconductor, integrated research, development, and SiC manufacturing site.

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media