BEV advancements are driving sales, but vehicle safety and reliability will ensure long-term viability

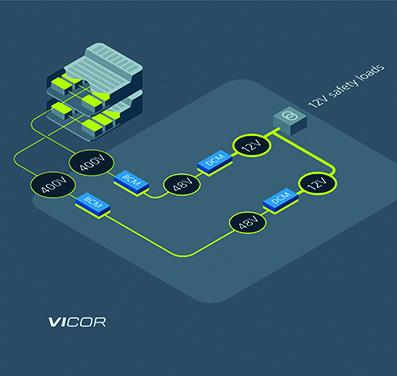

Innovative power architectures using power modules provide power redundancy and improve overall safety and system performance By Patrick Kowalyk, Automotive FAE,Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

The MRigidCSP packaging technology for battery management applications is designed to decrease on-resistance while increasing mechanical strength. It is offered on Alpha and Omega Semiconductor’s AOCR33105E, a 12V common drain dual N-channel MOSFET. It is suitable for battery applications in smartphones, tablets and ultra-thin notebooks, advises the company.

The MRigidCSP packaging technology for battery management applications is designed to decrease on-resistance while increasing mechanical strength. It is offered on Alpha and Omega Semiconductor’s AOCR33105E, a 12V common drain dual N-channel MOSFET. It is suitable for battery applications in smartphones, tablets and ultra-thin notebooks, advises the company.

Fast charging, which requires lower power loss in the battery management circuit, is typically used for portable devices but as the charging currents increase, ultra-low electrical resistance is needed to improve performance. In standard wafer level chip scale packages (WL-CSPs), the substrate can be a significant portion of the total resistance when back-to-back MOSFETs are employed in battery management applications. While a thinner substrate reduces overall resistance it also “drastically reduces the package’s mechanical strength” says Alpha and Omega Semiconductor (AOS). This reduction can lead to more stress during the PCB assembly reflow process, potentially causing warping or cracking in the die and failure in the application. The AOCR33105E is designed with the latest trench power MOSFET technology in a common drain configuration for design simplicity. It features ultra-low on resistance with ESD protection to improve performance and safety in battery management, such as protection switches and mobile battery charging and discharging circuits.

“AOS designed the MRigidCSP package technology to be used with high-aspect ratio CSP die sizes, helping to alleviate one of the major causes of battery management application production problems. Our advanced CSP construction delivers a significantly strengthened battery MOSFET that won’t warp or break during the board manufacturing process, making it a higher performance and higher reliability solution,” according to Peter H. Wilson, AOS’s senior MOSFET product line marketing director.

The AOCR33105E in the MRigidCSP package is immediately available in production quantities with a lead time of 14 to 16 weeks. It is RoHS 2.0 compliant and is halogen-free.

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media