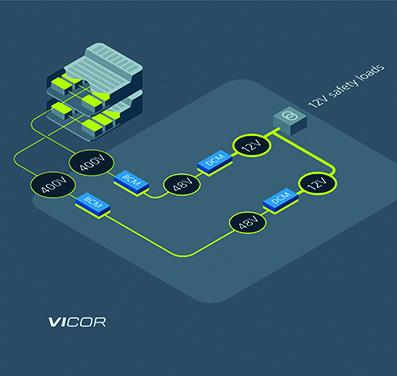

BEV advancements are driving sales, but vehicle safety and reliability will ensure long-term viability

Innovative power architectures using power modules provide power redundancy and improve overall safety and system performance By Patrick Kowalyk, Automotive FAE,Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

The AEM13920 power management IC can maximise the energy harvested from a combination of two sources, including photovoltaic (PV) cells, a thermo-electric generator (TEG), RF energy harvester or pulsed (kinetic) energy sources. The dual-source capability IC can be used in place of specialised PMICs optimised for a single type of energy harvester for energy harvesting in small electronics devices such as remote controls, PC peripherals and wireless sensors. For example, using the PMIC, a remote control could have separate PV cells on its front and rear, to maintain an energy input whether the device is left face up or face down. Another use case could be a smart wireless light switch able to operate on mechanical energy for short RF transmissions and on stored mechanical or light energy for longer operations such as downloading and installing a firmware update.

The AEM13920 power management IC can maximise the energy harvested from a combination of two sources, including photovoltaic (PV) cells, a thermo-electric generator (TEG), RF energy harvester or pulsed (kinetic) energy sources. The dual-source capability IC can be used in place of specialised PMICs optimised for a single type of energy harvester for energy harvesting in small electronics devices such as remote controls, PC peripherals and wireless sensors. For example, using the PMIC, a remote control could have separate PV cells on its front and rear, to maintain an energy input whether the device is left face up or face down. Another use case could be a smart wireless light switch able to operate on mechanical energy for short RF transmissions and on stored mechanical or light energy for longer operations such as downloading and installing a firmware update.

The PMIC achieves high source-to-storage and storage-to-load conversion efficiencies of higher than 90%. Independent maximum power point tracking (MPPT) algorithms for each source, and a low cold start input condition of 275mV/5µW, maximise the amount of energy drawn from any type of harvester, says e-peas. The AEM13920 also offers the option of constant source-voltage regulation.

Use of the AEM13920 simplifies power system development and minimises component count and bill of materials cost, because the single chip integrates all the functions required to store and use energy from an external harvester. Two independent on-chip boost converters manage source voltage conversion and the supply to the storage element. A separate on-chip buck regulator converts the output from the storage element to a fixed voltage required by the application between 0.6V and 2.5V. The AEM13920 also manages a 5V power input, which can be used to charge the storage element in the event of a prolonged period of operation without an input from an energy harvester.

New features include average power monitoring whereby a circuit measures total energy transferred from each of the two sources to storage and total energy supplied to the load. This enables the host microcontroller to calculate the state of charge of the storage element and to monitor system operation in detail.

It also has an I2C interface for control of 33 register settings by the host MCU, and for system data read-outs.

System monitoring and protection features include thermal monitoring of the storage element, selectable over-charge and over-discharge limits for protection of the storage element and shipping mode to protect the storage element.

The AEM13920 is compatible with many types of rechargeable batteries and storage elements, including lithium-polymer, LiFP and li-ceramic batteries, and hybrid lithium capacitors.

It is supplied in a 40-pin QFN package with a board footprint of 5.0 x 5.0mm. It is available for sampling now with a 2AAEM13920J051 evaluation board also available.

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media