BEV advancements are driving sales, but vehicle safety and reliability will ensure long-term viability

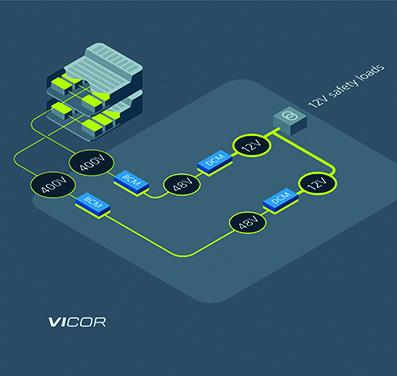

Innovative power architectures using power modules provide power redundancy and improve overall safety and system performance By Patrick Kowalyk, Automotive FAE,Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

The 40V-rated FCQFN devices are available with an on-resistance value of 4.3mΩ and the chip size is 3.0 x 4.0mm. The 100V HEMTs are offered with RDS(on) of 2.8mΩ and dimensions of 3.0 x 5.0mm and a 1.8mΩ model which has a chip size of 4.0 x 6.0mm. The 150V-rated parts measure 4.0 x 6.0mm and are available with 3.9mΩ and 7.0mΩ RDS(on).

The 1.8mΩ 100V HEMTs are packaged in FCQFN 4.0 x 6.0mm and is therefore pin-for-pin compatible with the 3.9mΩ and 7.0mΩ 150V parts.

The 40V parts, using Innoscience’s latest GaN processes, achieve industry-leading performance, claims the company, with best in class FOM (figure of merit) values for Qgg*Ron and Idss*Ron.

Low drain and gate leakage currents enable the HEMTs to be used in mobile markets and direct battery-connected applications as well as USB Type C buck-boost converters in laptops. Innoscience says that its latest generation process enables it to maintain very tight control of the epitaxy, resulting in a very uniform threshold voltage and on-resistance, leading to a very high wafer yield.

100V HEMT devices are suitable for DC/DC conversion at power levels of up to 2kW and can achieve up to 8kW when used in parallel configuration.

The 150V models are suitable for industrial applications, including solar installations. They have been designed to be rugged so they do not need the industry-standard 80% derating to be applied (i.e. they are rated at 100% of their voltage), explains Innoscience.

All of the new HEMTs have been tested to and exceeded JEDEC and the GaN-specific JEP 180 standards.

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media