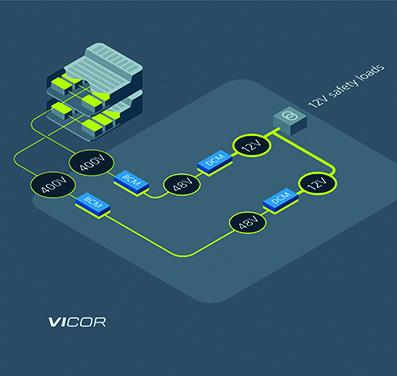

BEV advancements are driving sales, but vehicle safety and reliability will ensure long-term viability

Innovative power architectures using power modules provide power redundancy and improve overall safety and system performance By Patrick Kowalyk, Automotive FAE,Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

The MLCCs have a reversed termination for low ESL. In addition to what is believes to be the industry’s first 0.18mm profile package, the footprint is just 0.5 x 1.0mm for 1µF capacitance.

The MLCCs have a reversed termination for low ESL. In addition to what is believes to be the industry’s first 0.18mm profile package, the footprint is just 0.5 x 1.0mm for 1µF capacitance.

They use Murata’s proprietary thin-layer forming and high precision lamination technology, advanced material atomisation and homogenisation techniques to achieve around a 20% reduction in component height compared with existing parts. The small form factor and dimensions allow the MLCC to fit on the reverse side of circuit boards. They can also allow for positioning amongst solder ball terminations, locating the parts in optimum positions for decoupling of processor power rails, close to the die. This allows fewer capacitors to be used, saving cost, and increasing system reliability, says Murata.

The LCC series has low ESR and reduced ESL which reduces the high frequency impedance of the capacitors and improves circuit performance for low voltage, compute-intensive applications, including ADAS (automotive advanced driver assistance systems).

The automotive-grade LLC series complies with AEC-Q200 requirements and passes the 1000 temperature cycle test and temperature/humidity endurance test of 85°C at 80 to 85% humidity for 1000 hours.

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media